| Verification of composite slab-Bondek II |

| Ultimate limit state |

|

| The design ultimate loading is : |

w = |

|

kN/m2 |

|

|

|

|

|

|

| Effective span: |

Le= |

|

m |

|

|

|

|

|

|

| The continous slab will be designed as a series of simply supported spans. |

|

|

|

|

|

|

| The mid-span bending moment is: |

|

|

kNm/m |

|

|

|

|

|

|

| The design vertical shear is: |

|

|

kN/m |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| 1) Bending resistance check |

|

| There must be full shear connection, so that the design compressive force in the concrete, Nc,f is : |

| |

|

|

kN/m |

|

|

|

|

|

| The depth of the slab in compression, for full shear connection, is: |

| |

|

|

mm |

< |

|

|

mm |

|

| Therefore, the plastic neutral axis is above the sheeting. The distribution of longitudinal bending stresses is shown in Figure 1. |

| The design resistance to sagging bending is, for full shear connection: |

Figure 1 Cross-section of composite slab, and stress blocks for sagging bending |

| |

|

|

kNm/m |

< |

MEd= |

|

kNm/m |

Recalculate |

|

| |

|

|

|

|

|

|

|

|

| 2) Vertical shear resistance check |

| The recommended value for minimum value (umin) is: |

| |

|

|

N/mm2 |

|

|

|

|

|

| in which dp taken as not less than 200. In this problem, dp is taken as 200mm. |

| The design resistance to vertical shear is: |

| |

|

|

kN/m |

< |

VEd= |

|

kN/m |

Recalculate |

| with |

b is the pitch of deck ribs |

taken as |

|

mm |

|

|

|

|

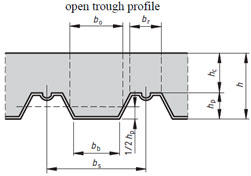

For open profiles, their effective width should be taken as the mean width. |

| b0 is the effective width of the concrete ribs, |

taken as |

|

mm |

|

|

|

|

For re-entrant profiles, the minimum width should be used. |

| dp is the depth to the centroidal axis, |

taken as |

|

mm |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| 3) Longitudinal shear check |

|

| For longitudinal shear, it is assumed that there is no end anchorage, so that clause 9.7.3 is applicable. |

|

| a) m-k method |

|

|

|

|

|

|

|

|

| The design shear resistance is: |

|

|

|

|

|

|

|

|

| |

|

|

kN/m |

|

|

|

|

|

|

| The value used are: |

|

|

|

|

|

|

|

|

| |

b = |

1.0 |

m |

|

dp = |

|

mm |

|

|

| |

Ls = l/4 = |

0 |

mm |

|

Ap = |

|

mm2 |

|

|

| |

m = |

|

N/mm2 |

|

k = |

|

N/mm2 |

|

|

| This value must not be exceeded by the vertical shear in the slab. Therefor, Vl,Rd is taken as: |

|

| |

|

|

kN/m |

< |

VEd= |

|

kN/m |

Recalculate |

If this method is not verified longitudinal shear check, uses partial connection theory |

| |

|

|

|

|

|

|

|

|

|

| Serviceability limit state |

|

| Control of cracking of concrete |

|

| As the slab is designed as simply supported, only anti-crack reinforcement is needed. The cross-sectional area of the reinforcement above the ribs should be not less than 0.2% for un-propped construction. |

|

| |

min As = 0.002 x b x hc = |

|

mm2/m |

|

|

|

|

|

|

| and the A252 mesh used here is sufficient. |

with As = 252 mm2/m |

(f8 a200) |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| Deflection |

|

| Second moment of area |

|

| The short-term elastic moduli and modular ratios are: |

|

| |

|

|

|

|

|

|

|

|

|

| For buildings, EN 1994 permits the simplification that all strains may be assumed to be twice their short-term value. |

|

| The long-term elastic moduli and modular ratios are: |

|

| |

|

|

|

|

|

|

|

|

|

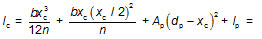

| The depth of neutral axis (counted from the top of slab) is then given by the 'first moments of area' equation: |

See R.P.JOHNSON's books |

| |

|

|

|

|

|

|

|

|

|

| Hence |

|

|

mm |

|

|

|

|

|

|

| The second moment of area is: |

|

| |

|

|

mm4/m |

|

|

|

|

|

|

| The total load is taken as, using the frequent combination for calculating the deflection of composite slab: |

|

| |

|

|

kN/m2 |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| For the calculation of delecftion, firstly, the slab is considered to be simply supprted. |

|

| The mid-span deflection is: |

|

|

|

|

|

|

|

If the deflection is greater than the limit value, recalculate as the continuous slab. |

| |

|

|

mm |

|

|

|

|

|

|

| The allowable deflection is: |

|

|

|

|

|

|

|

A more accurate calculation for the continuous slab, assuming 15% of each span to be cracked |

| |

|

|

mm |

< |

|

|

mm |

Recalculate |

|

| |

|

|

|

|

|

|

|

|

|

| All design checks are OK at both the ultimate limit state and the serviceability limit state. |

|

| |

|

|

|

|

|

|

|

|

|